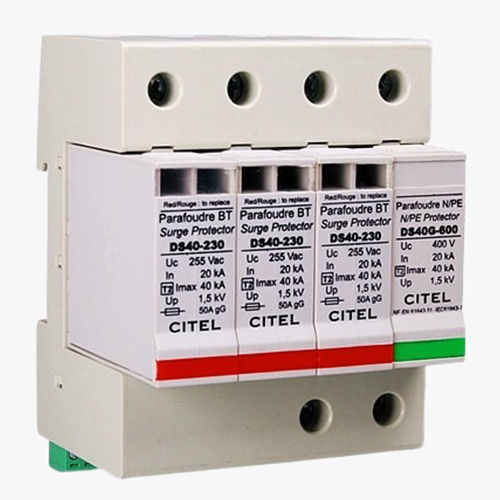

GS ELECTROCONTROLS PRIVATE LIMITED is professionally managed organization and pioneer in providing top quality Solutions in Lightning Protection and Grounding system to it's customers. The group associated with extremely competent technical engineers as well as experts operate the organization.

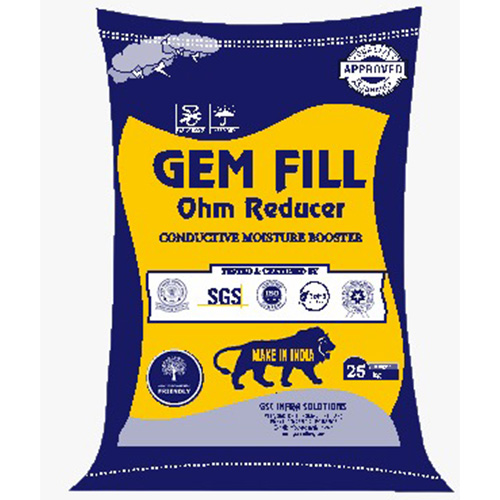

Providing the highest quality grounding system to the valuable client. We now have an enormous stock available throughout the year and we can also deliver products at a short notice. Customer satisfaction is a priority to us and we leverage all our experience and expertise to provide world class services.

Read More

To schedule time to speak with one of our sales representatives, complete the form, then click "next" to choose a date and time that works for you.

Where We Are And What We Are. It Is Just Because The Love And Appreciation Of Our Esteemed Customers.

One of my friends suggested me the name of GS Electrocontrols Pvt. Ltd. when I was looking for the Plate Earthing Solutions. Now I am thankful to him for suggesting such a good brand for earthing solutions as they supplied best quality products with great service delivery.

We were exploring the Internet for the best company for earthing solutions when we came across GS India on Google and decided to contact them for our needs. We want to thank them for their high-quality products. Thank you GS Electrocontrols Pvt Ltd.

We would like to recommend GS Electrocontrols Pvt. Ltd. for their quality products because we always received the best products when we are in need. The way they treat their clients is just fabulous. We want to wish them all the best wishes for all their future endeavours.

GS Electrocontrols Pvt. Ltd. supplied us Chemical Earthing Electrode two months ago. We must say that the quality was excellent, and their way of customer treatment brightened our day. If you're seeking earthing solutions, you must connect with them.